ACTIVITY REPORT

Operations

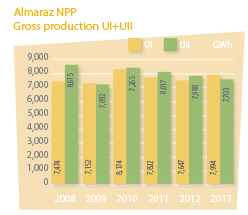

ALMARAZ PLANT

In 2013 the gross output generated by the two Almaraz Nuclear Power Plant units was 15,696.5 million kWh, and the net joint production was 15,108.7 million kWh.

Individually, the gross electricity production of Unit I was 7993.9 million kWh, and Unit II 7702.6 million kWh.

Almaraz NPP had a gross accumulated electricity production (from 1 May 1981 to 31 December 2013) of 447,085.6 million kWh (226,001.5 UI and 221,084.2 UII).

The year has involved important and complex activities for Almaraz Nuclear Plant, as each of the units were stopped for refuelling and maintenance at the start and at the end of the year.

The twenty-second refuelling outage for Unit I was completed in January. After coupling to the grid on 10 January, an electrical fault in the alternator excitation system caused two automatic shutdowns, and an unscheduled unit outage was performed as a preventative measure for a comprehensive overhauls of the exciter and voltage regulator, and it was re-connected to the grid on 10 February. The unit experienced another automatic reactor shutdown due to a very low level signal in steam generator SG-3, on 22 February. It was connected to the grid on 24 February and remained coupled and operational at full capacity for the remainder of the year.

On 23 May Unit II experienced an automatic reactor shutdown as a result of the prior stoppage of the turbine caused by the action of an electric generator protection system. After this stoppage, the unit was brought to cold shutdown so that a number of preventive activities could be carried out. After this work, the unit was coupled to the grid on 4 June, and operated at full power for the entire period until decoupled for refuelling on 23 November.

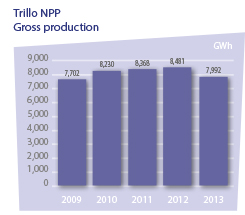

TRILLO PLANT

The gross production of Trillo Nuclear Power Plant from 1 January to 31 December 2013 totalled 7.992 million kWh with a net production of 7.487 million kWh during this period.

Since the commencement of operations in 1988 up to the end of 2013, the Plant has generated a total of 205,170 million kilowatt hours electricity, and at 20:10 hours on 22 April the cumulative production milestone of 200,000 million kWh was reached.

2013 had a special meaning for Trillo Nuclear Power Plant: 14 and 22May respectively marked the 25th anniversary of the first criticalityof the reactor and the first coupling to the power grid, and 6 Augustmarked 25 years since the start of commercial operation.

The twenty-fifth outage for refuelling and general maintenance took place between 17 May and 23 June 2013 and during the year there were no automatic reactor stoppages.

In July, there was an outage to check the alternator bearing, and in December it was necessary to reduce reactor power to 0% and to cool the plant to repair an oil leak in the radial bearing of low pressure turbine No. 3.

There were 23 containers with a total of 483 fuel elements in Individual Temporary Storage (ITS) on 31 December 2013.

Refuelling

OUTAGES

ALMARAZ PLANT

The programme for the twenty-second outage for refuelling and routine maintenance at Unit I took 61 days from 10 November 2012 to 10 January 2013.

The work involved the collaboration of over 70 specialised service companies employing about 1,100 individuals in addition to the usual stable workforce.

Several design modifications were implemented related to the improvements involved in responses to ITCs issued by the NSC within the framework of the “Stress Test” performed in the European Union. The design modifications included work to make the electrical systems independent, implementation of an alternative shutdown panel, changes associated with increasing the seismic margin, improvements to the supply lines to the turbopump, and the start of work to implement the new redundant filtration unit in the fuel building, work which will be continued in September 2014.

The twenty-first refuelling and general maintenance of Unit II was took place between 23 November 2013 and 25 January 2014. The collaboration of over 70 specialised service companies employing about 1,200 individuals were involved, in addition to the usual stable workforce during these 63 days.

The activities carried out involved 65 design modifications including: implementing the alternative shutdown panel, the redundant filtration unit in the fuel building, work to make the electrical systems independent, increasing the seismic margin for equipment, connections to external tanks and other connections, as well as design modifications for the transition to the new “NFPA-805” fire protection standards (passive protections, new doors and fire doors).

TRILLO PLANT

The twenty-fifth outage for refuelling and general maintenance took place between 17 May and 23 June 2013.

The programme of activities was implemented within 36 days and involved the collaboration of 1,142 workers from 45 specialised service companies in addition to the usual stable workforce.

There were almost 4,000 preventive and corrective maintenance actions, inspections and plant improvements, including the primary circuit bleed & feed design modification, ultrasonic inspection of the fuel element centering pins, changing a main pump motor, design modifications arising from the stress test analysis, containment pressure test, revisions required to components included in the pumps and valves manuals, reviewing the pilot valves in one of the primary steam loops, visual inspection of the tubular plate in the three generators and inspection of the hydrocyclones in two secondary side generators.

Radiological

SAFETY AND PROTECTION

Safe operation of the plants under any circumstance and situation is the first and most important consideration, in order to ensure adequate protection of plant personnel, the public and the environment. All safety-related actions are performed by authorised personnel, properly trained with the necessary resources, subject to administrative controls, implementing procedures which are approved and monitored. Their knowledge and skills are updated on an ongoing basis as part of the CNAT framework training plan. This plan is intended for internal and external staff, to ensure that everyone involved with the installation has the knowledge and skills required.

During 2013 the installations operated completely normally, without producing any significant incident that affected nuclear safety or radiological protection, employees, or the plant environment.

From the measurements obtained during 2013, the results show that the dose rate of professionally exposed personnel was far below the legal limits established. In the case of Almaraz, the collective staff dose totalled 573.26 mSv per person for the combination of the two units, and at the Trillo Plant, the dose totalled 224 mSv per person, one of the best years for collective doses during the entire history of the installation.

Technological

UPDATING

CNAT makes strenuous efforts every year to improve and update facilities, and during 2013 it maintained the investment levels of recent years.

This year Almaraz Nuclear Power Plant continued to develop improvements resulting from the tests conducted after the Fukushima accident, and others based on the operating permit, equipping the Plant with a new alternative stoppage panel in UII (to be implemented in UI during 2014), as well as a new seismic fire protection system common to both units. The Renovation Plan for instrumentation and control equipment included the modernisation of loop boards for the Steam Generator relief valves in UII (UI during 2014) and this is ongoing along with other modernisation improvements to the auxiliary feedwater turbo control.

In addition to the improvements resulting from Fukushima, Trillo Nuclear Power Plant has commissioned the new YG20 primary vibration monitoring system as part of the instrumentation and control equipment renovation plan, and the design has been finalized for the turbine and bypass control and protection system to be implemented in 2015. The electrical equipment renovation plan has continued and a new device to automatically synchronise the main alternator with the national grid has been installed, and the contract has been awarded for a new transformer to be installed in 2015.

Quality

Quality is intrinsic to all activities at CNAT and is the main source of confidence for our owners, the social environment, employees and business partners. The commitment to quality at CNAT has been recognised by the Spanish Association for Standardisation and Certification (Asociación Española de Normalización y Certificación - AENOR) by the award since 1995, of an official certificate attesting compliance of our Quality Management System with the UNE EN ISO 9001 standard for nuclear originated power. The quality certification was renewed in 2013 for total compliance, and runs until 2015.

We also voluntarily submit to international assessments to determine the degree of excellence of the organisation. These include WANO Peer Reviews and in September/October there was a Peer Review at the Trillo plant this year with a satisfactory overall result.

Continuous Improvement is part of the CNAT’s organisational culture and it is for this reason that we manage around 5,000 corrective and improvement actions, revisions and studies each year, based on internal and independent evaluation, as well as those based on self-assessments and internal suggestions by personnel.

Furthermore, in 2013 the various units have identified around 12,000 low-level incidents, with the aim of performing trend analyses and to enable the identification of preventive actions to avoid higher category incidents.